News

‘We don’t have any Oompa Loompas’: What life is like inside Haribo’s £92m West Yorkshire sweet factory

11 June 2021

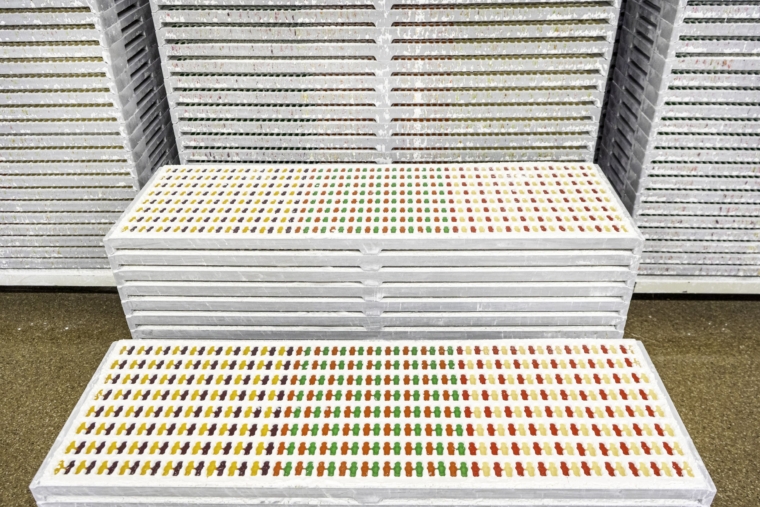

The Castleford workforce produces 30,000 tonnes of sweets including Haribo’s trademark Goldbears every year – helping the firm maintain its position as the UK’s leading sweets manufacturer

In the heart of a brightly lit factory building in West Yorkshire, thousands of red and gold gummy bears are bouncing gleefully down a metal tube and then back up a mini escalator.

Workers are using torches to carefully inspect purple and orange jelly snakes as they cool down in their trays nearby. In the distance, robot hands are putting bags of jelly babies into boxes at an astonishing rate of 160 a minute.

Welcome to the inner world of Haribo, where billions of sweets are lovingly made before beginning their long journey towards the homes of families across the UK.

“Just look at these,” says Frank Windmann, the factory’s German-born operations director, with an almost child-like sense of wonderment as he points out the thousands of bears going up the tiny escalator. “I’ve been with Haribo for 26 years,” he adds as an unmanned, laser-guided forklift truck rolls past on its way to collect more jelly snakes.

“We all knew about Haribo as kids back home. I started out doing a summer job and then joined the graduate scheme. I’ve been with the firm ever since. Every day brings something interesting. I love my job now as much as I did then.”

Haribo was founded in Germany in 1920 by confectioner Hans Riegel and the name is a contraction of his name and of his home town, Bonn, where Mr Windmann also grew up.

Helped by his wife, Gertrud, Mr Riegel started out making jelly sweets in a small kitchen with little more than a sack of sugar, a copper pot and a rolling pin. But from there, Haribo has become a global market leader.

It employs more than 7,000 people in 16 locations around the world, including this £92m new site at Castleford. The workforce here produces 30,000 tonnes of sweets including Haribo’s trademark Goldbears every year – helping the firm maintain its position as the UK’s leading sweets manufacturer.

And quite a few of those staff end up staying for a long time, such as Julie Beaman, who has worked for the firm for 40 years. Her daughter Georgia, 23, has also joined her at Haribo.

“A lot has changed,” says Julie, who works in the marketing department in the offices above the factory where the bears are currently being made. “In the old days we used to do more traditional sweets like dolly mixtures and of course we have the robots now.

“But it’s the people who really make this place and they haven’t changed. I’ve always felt there is a tight-knit, family feel here. I’ve made friends for life. Georgia came on a summer trip when she was four and now she works here too.”

In the sales department next door, Steve Noble has also worked for the firm for 27 years and says he grew up with a lot of the other staff. He even remembers Georgia being born. Now his son, Ed, works in the same department as well.

“My dad also worked in confectionery sales,” Steve says. “Growing up, our house was full of samples, including sweets that were about to go on the market. I was the ideal product tester. I had a lot of friends. People are proud to work here. That’s why they stay.”

In product development, Jenny Opala says customers are fiercely loyal and even small changes spark a huge public debate. One hot topic on social media recently has been whether a sweet in every bag of Starmix, Haribo’s bestselling treats in the UK, is a UFO or a fried egg.* (It’s a fried egg.)

“We’ve even had calls from women who have been proposed to with the jelly ring in a bag of Starmix,” she says. “They want to know how best to preserve it.”

While Goldbears are still produced to the same basic recipe as the first one that was ever made, with natural flavourings and colours, tastes are constantly evolving and Haribo has been developing a vegetarian range.

The firm is also reformulating its sweets under the ethos of ensuring they are “just sweet enough”, including bags of Fruitilicious with 30 per cent less sugar and Jelly Babies which have 25 per cent less sugar than their competitors.

Meanwhile, it is also investing £22m in additional manufacturing and new high-skilled engineering jobs at the Castleford site to improve efficiency and reduce costs while making more sweets.

The first of the new production lines have already been built and engineers in blue shirts can be seen carrying out final adjustments before they go into service. On another floor, giant orange robots can be seen picking up boxes and stacking them on to pallets.

“We wanted to invest in new technology and create more high-skilled jobs for the local community,” says Jon Hughes, Haribo’s UK managing director. “It will help us stay at the top of the UK market and produce a broader variety of great tasting sweets.

“The greatest thing about Haribo is the people who make them. They are proud of what they do and that’s why we have so many long-stayers.”

Mr Hughes says the firm is taking great strides in reducing sugar. “We’ll continue to lead the way in using only as much sugar as we need to deliver the taste and texture that our customers love. We all remember our childhoods of going to the sweet shop. For me, it was a bag of pear drops. Sweets are treats and, in difficult times like this, we all need a treat from time to time.”

Downstairs in the sweet factory’s great kitchen, Mr Windmann is now looking into a huge metal vat where jelly is being mixed for the next consignment of sweets that will soon be making their way to shops across the country.

Signs on the stairs invite the workers to share the firm’s motto of having a child-like happiness.

“It isn’t like what most people think,” Mr Hughes says as he walks out of the kitchen door. “We don’t have any Oompa Loompas.”